- 01562744788

- enquiries@central-profiles.co.uk

- Mon - Fri: 8am - 5pm

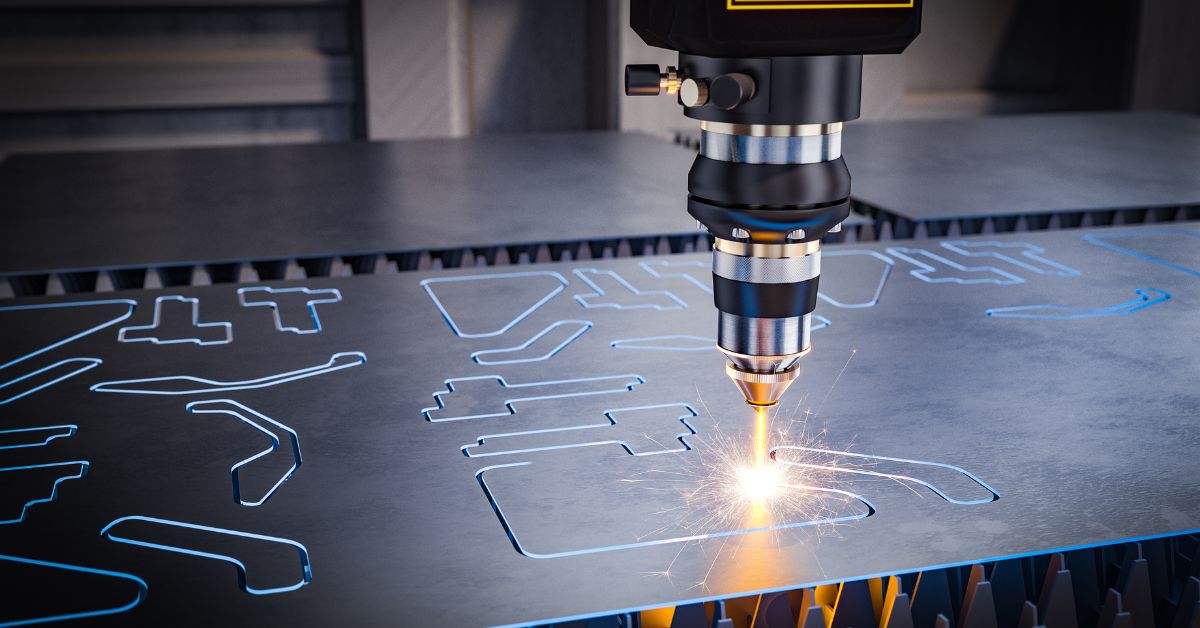

In the world of manufacturing, precision cutting is a vital component in the production of many products. The advancement of technology has brought forth new cutting methods that have revolutionized the way products are made. One of these cutting methods is laser cutting.

Laser cutting is an exact and accurate method using a laser beam to cut materials such as metal, plastic, and wood. This method is widely used in a variety of industries such as automotive, aerospace, electronics, and many others.

What is Laser Cutting?

Laser cutting is a process in which a laser beam is used to cut the material into a specific shape or pattern. The laser beam is generated by a laser source and is then directed onto the material to be cut. The beam is focused and the material is melted or burned away, leaving behind a clean, precise cut.

Advantages of Laser Cutting Services

Laser cutting is renowned for its precision and accuracy. The laser beam can be focused to a very small point, making it possible to cut intricate shapes and patterns with ease. This level of precision is unmatched by traditional cutting methods, making it an ideal choice for many industries.

Laser cutting is much faster than traditional cutting methods, making it highly efficient. This speed is particularly beneficial in high-volume production runs where time is of the essence.

In traditional cutting methods, the cutting tool can become worn or damaged over time, leading to inaccuracies in the cuts. With laser cutting, there is no physical contact between the cutting tool and the material, so there is no wear and tear. This means that the cuts are always precise and accurate.

Laser cutting is a highly consistent process, ensuring that each cut is of the same quality and accuracy. This is particularly important in industries where quality control is of utmost importance.

Laser cutting can be automated, making it possible to produce large quantities of products quickly and efficiently. The automation process eliminates human error, leading to consistent quality and accuracy.

Applications of Laser Cutting Services

The automotive industry is a major user of laser cutting services. Laser cutting is used to produce car body parts, engine components, and other automotive components. The precision and accuracy of the cuts ensure that the parts fit together perfectly, resulting in a high-quality finished product.

The aerospace industry is another major user of laser cutting services. Laser cutting is used to produce aircraft components such as wing skins, fuselage sections, and other parts. The precision and accuracy of the cuts are critical in ensuring the safety of the aircraft.

The electronics industry uses laser cutting to produce printed circuit boards and other components. The precision and accuracy of the cuts ensure that the components fit together perfectly, resulting in a high-quality finished product.

The medical industry uses laser cutting to produce medical devices such as surgical instruments and implants. The precision and accuracy of the cuts are critical in ensuring the safety and effectiveness of the devices.

Conclusion

Laser cutting services are a highly precise and accurate cutting method that has revolutionized the way products are made. Its precision, speed, consistency, and automation make it an ideal choice for many industries, including automotive, aerospace, electronics, and medical.

We started out in 1999 and have grown continually through an ongoing investment in machinery, software and people, even during the downturn.

© 2021 Central Profiles. All Rights Reserved. Website by Freestart Digital