- 01562744788

- enquiries@central-profiles.co.uk

- Mon - Fri: 8am - 5pm

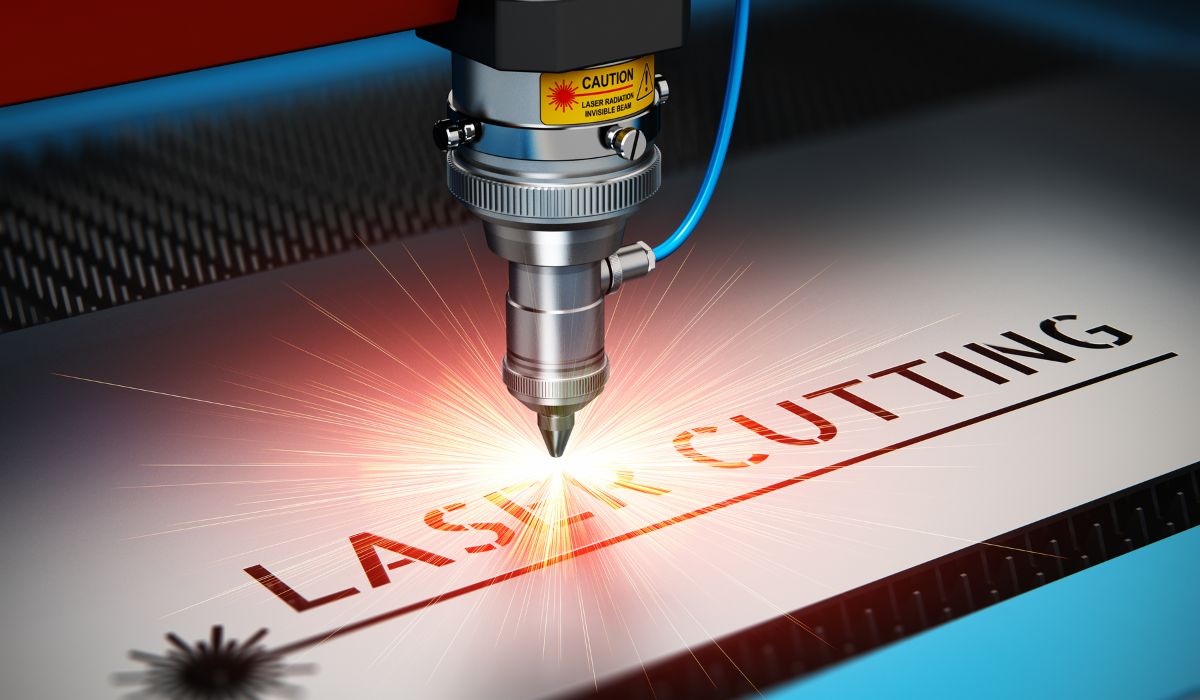

Steel laser cutting is a precise and efficient method of cutting steel sheets and plates using laser beams. It is a popular choice in industries such as automotive, aerospace, and construction due to its high accuracy and speed. Steel laser cutting machines use CNC technology to control the cutting process and produce intricate shapes and patterns with ease. The process involves directing a high-powered laser beam at the steel surface, which melts and evaporates the material, leaving behind a clean and precise cut. Metal cutting lasers are versatile tools for steel fabrication and can cut through a range of materials including aluminium and stainless steel.

Steel laser cutting is a highly precise and efficient process that has revolutionised the manufacturing industry. It offers a number of advantages over traditional methods such as plasma cutting and water jet cutting. One of the major benefits of using a laser cutter for steel fabrication is the ability to cut through thick materials with a high level of accuracy and speed. Additionally, CNC laser cutters for steel can be programmed to cut complex shapes and designs with ease, reducing production time and costs. Other advantages of laser-cutting steel include minimal waste, cleaner cuts, and the ability to cut a wide range of materials. Overall, the benefits of using a laser cutter for steel fabrication make it an ideal choice for businesses looking to optimise their manufacturing processes.

When it comes to metal cutting, lasers have become an indispensable tool for the industry. CO2 lasers for metal cutting and fibre lasers used in metal processing are two popular types of lasers utilised in the industry. CO2 lasers are widely used due to their high power output and ability to cut thick steel sheets with precision. Fibre lasers, on the other hand, are known for their speed and efficiency in cutting thinner sheets of metal. Both types of lasers have their unique advantages and can be used for a variety of applications in the metal-cutting industry. By understanding the differences between these two laser types, businesses can choose the right laser technology to optimise their metal-cutting process.

Choosing the right steel laser cutter for your business needs can be a daunting task. With so many options available, it can be challenging to know where to start. However, by considering several critical factors, you can make an informed decision and select a suitable machine that meets your specific requirements. Factors to consider when choosing a steel laser cutter include the type of materials you need to cut, the thickness of the material, the size of the machine, and the precision required. By picking the right type of machine for your business needs, you can increase efficiency, productivity, and profitability.

Conclusion

Steel laser cutting is a highly precise and efficient method for cutting metal sheets and plates, with numerous benefits for various industries. From faster production times to minimal material wastage and superior quality, the advantages of steel laser cutting are hard to ignore. However, to leverage the full potential of this technology, businesses must optimise their websites for SEO ranking. By incorporating relevant keywords, creating quality content, and ensuring website usability and accessibility, businesses can increase their online visibility, attract more traffic, and ultimately, drive sales and growth. With the right SEO strategies, steel laser-cutting companies can expand their reach and establish themselves as industry leaders.

We started out in 1999 and have grown continually through an ongoing investment in machinery, software and people, even during the downturn.

© 2021 Central Profiles. All Rights Reserved. Website by Freestart Digital